Plataine extends its digital thread technology

Plataine, a leading provider of AI-based manufacturing optimisation solutions, has extended its cloud-based automated Digital Thread technology, to help manufacturers working with composite materials, mitigate current global supply chain challenges and improve on time delivery.

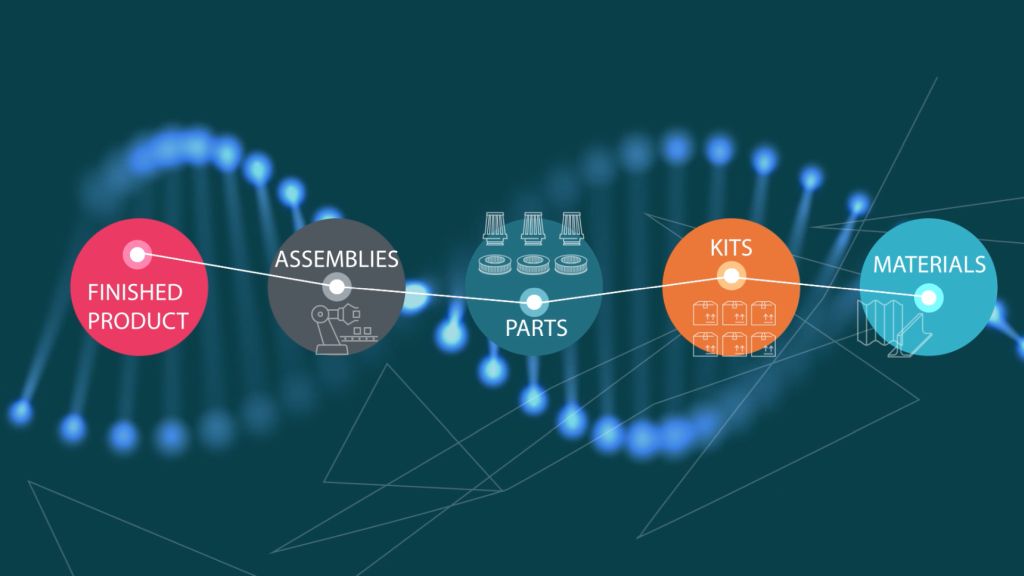

The Digital Thread delivers a holistic view of an asset or material across its entire lifecycle, and Plataine’s newest capabilities use cloud-based technology that enables manufacturers to log the complete genealogy of a product, stretching across multiple sites and organisations. This creates a holistic view – from raw material to finished part – available to anyone who has been provided with the credentials to access the information.

Current supply chain challenges such as soaring raw material and transportation costs, and acute shortages of labour and components present unprecedented challenges to any manufacturer. Raw material manufacturers can now make a ‘Digital ID’ available for each material they produce, allowing all relevant stakeholders in the supply chain to access any approved information, including material properties, material history, shelf life, defects and fault details. Part or assembly manufacturers can now automate and accelerate recall scenarios, reducing scrap and improving first-time quality. Full traceability also means that production floors in highly regulated industries, such as Aerospace, are always audit-ready.

In an era of labour shortages, process automation frees up staff for other, value-added, tasks. Plataine’s technology delivers automation wherever possible, from material receiving, through movement and consumption. One particular benefit is automated tracking of time sensitive raw material, ensuring exposure time limits are not exceeded. All this removes potential for human error, leading to reduced material waste, better inventory planning, reduced re-work and scrap.

Avner Ben-Bassat, President & CEO at Plataine, said: “Our expanded Digital Thread technology allows manufacturing organisations to securely share material and product data, and enables managers to know what is happening at all points along the supply chain and production lines. We are excited to help manufacturers better cope with the recent supply chain challenges, reduce costs and improve quality control, while freeing overworked staff from mundane tasks.”

Come meet the company at its SAMPE booth, #H24 to discuss the future of manufacturing during May 23-26 at Charlotte, NC.